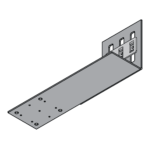

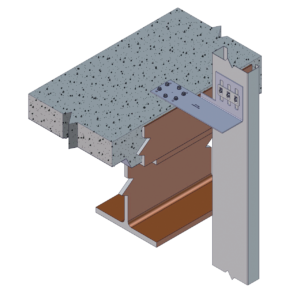

The STP slide strut attaches the bypass curtain wall stud to the building structure, allowing for vertical deflection while maintaining lateral rigidity. This clip provides a non-frictional connection and prevents vertical load transfers into the curtain wall. The insert is pre-installed to the clip, making installation quick, easy, and efficient.

Features & Benefits

- Unique insert allows for 2″ total vertical deflection

- Maintains lateral rigidity

- Pre-punched holes for #12 framing screws

Material Composition

- Mill certified steel

- ASTM A653/A653M

- Clip

– Material thickness: 118 mil

– Yield strength: 57 ksi

– Tensile strength: 65 ksi

– G90 galvanized coating - Insert

– Material thickness: 97 mil

– Yield strength: 57 ksi

– Tensile strength: 65 ksi

– G90 galvanized coating

Allowable Loads

| Model No. | Stud Thickness | F1 Allowable Loads (lbs) | ||||

|---|---|---|---|---|---|---|

| Mils | Gauge | Fy (ksi) | 2 #12 Screws * | |||

| STP 900 1200 1500 |

||||||

| 33EQS | 20 | 57 | 710 | |||

| 43EQS | 18 | 57 | 710 | |||

| 33 | 20 | 33 | 710 | |||

| 43 | 18 | 33 | 710 | |||

| 54 | 16 | 50 | 710 | |||

| 68 | 14 | 50 | 710 | |||

| 97 | 12 | 50 | 710 | |||

| 118 | 10 | 50 | 710 | |||

| Maximum Allowable Clip Load | 710 | |||||

| Model No. | Stud Thickness | F1 Allowable Loads (lbs) | ||||

|---|---|---|---|---|---|---|

| Mils | Gauge | Fy (ksi) | 2 #12 Screws* | |||

| STP 1800 2000 |

||||||

| 33EQS | 20 | 57 | 670 | |||

| 43EQS | 18 | 57 | 670 | |||

| 33 | 20 | 33 | 670 | |||

| 43 | 18 | 33 | 670 | |||

| 54 | 16 | 50 | 670 | |||

| 68 | 14 | 50 | 670 | |||

| 97 | 12 | 50 | 670 | |||

| 118 | 10 | 50 | 670 | |||

| Maximum Allowable Clip Load | 670 | |||||

Table Notes

- Allowable loads have not been increased for wind, seismic, or other factors.

- The allowable loads are based on the steel properties of the members being connected, per AISI S100.

- The nominal strength of the screw must be at least 3.75 times the allowable loads.

- Penetration of screws through joined materials should not be less than 3 exposed threads. Install and tighten screws in accordance with the screw manufacturer’s recommendations.

- Screw shear capacities are based on allowable strength design (ASD) and include a safety factor of 3.0.

- Allowable loads indicated on the table(s) are for force in single direction only. If more than one force is applied to the connection, the designer shall provide the combined forces check as required by AISI S100.

- The designer shall check the bending in the short leg of clip.

Quantity / Order Information

| Model No. | Width | Qty / Bucket | lbs / Bucket |

|---|---|---|---|

| STP-900 | 9″ | – | – |

| STP-1200 | 12″ | – | – |

| STP-1500 | 15″ | – | – |

| STP-1800 | 18″ | – | – |

| STP-2000 | 20″ | – | – |

All STP struts include inserts. Additional lengths available upon request.